FACILITIES AND EQUIPMENT

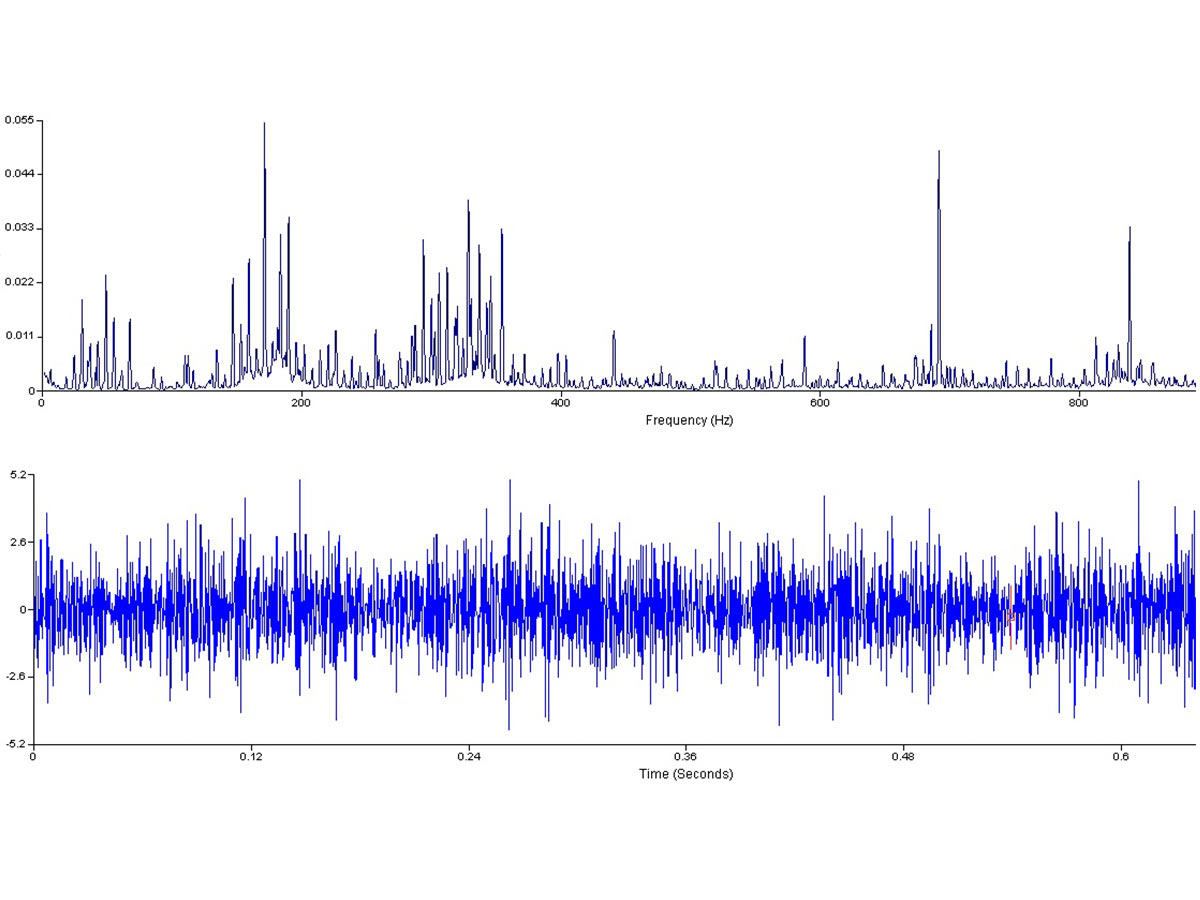

IN-SITU MACHINING AND VIBRATION ANALYSIS.

Northern Engineering operates out of a recently enlarged 24,000 square foot facility. It is equipped with state-of-the-art CNC equipment. In addition, we have a wide array of portable equipment, vibration analysis and a motion amplification system.

Our experts will measure and compare performance to OEM specs. And help you develop a plan before you experience downtime.

HERE TO KEEP YOUR EQUIPMENT IN TOP CONDITION.

Northern Engineering offers a comprehensive range of services and capabilities to keep your equipment in top condition. Our heavy investment in mobile diagnostic and repair equipment reduces costs and downtime.

EQUIPMENT LIST

NEW: Motion Amplification Services

Motion Amplification™ is a proprietary video processing technique that detects subtle motion and then amplifies that motion to a level visible with the naked eye.

This new system is changing the way companies monitor the condition of billions of dollars worth of plant machinery and manufacturing equipment.

Contact Northern Engineering for more information.